The thirty years of experience that ICA has accumulated in its studies on paints for wood has brought about the formulation of products which are more and more oriented towards maximum performance as far as chemical resistance and durability are concerned, and at the same time respect for the natural beauty of the wood. The range of UV products for prefinished parquet give optimum results whilst producing low solvent emission (VOC), guaranteeing the chemical-physical characteristics that are expected of a product for parquet such as hardness, chemical resistance and abrasion resistance. A correct balance between chemical and mechanical characteristics during the application cycle is essential to obtain an optimum final result. For more information on ICA products visit website www.icaamerica.biz

The results of various tests carried out in our laboratories on surfaces treated with UV cycles for prefinished parquet compared to surfaces treated with bicomponent solvent based polyurethane products for traditional parquet can be seen in the following table. The results of the UV cycles are comparable, and in some cases even superior to the polyurethane cycles. The most important test is probably that of abrasion resistance. This test in fact simulates the wear and tear on a painted parquet provoked by the tread of feet, using a taber abrasion meter with CS-17 wheels, loaded with a 1kg weight for 1000 revs.

- BASE COATS characterized for their excellent abrasion resistance, covering power and good sandability.

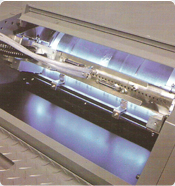

- TOP COATS excellent scratch resistance (both matt and gloss top coats), good hardness and chemical resistance, excellent distension. They are also applicable by laser roller.